Learn how to repair rust, step by step

Sure, you can lower your risk of rust and rust spots on your car by applying paint protection film to chip-prone areas like the front edge of the hood, and by frequently washing off road salt and waxing your vehicle regularly. But even then, you’re still going to get rust spots.

Learning how to repair rust isn’t hard, but it is time-consuming (mostly waiting for primer and paint to dry between steps). Plan to spend about $100 on supplies like sandpaper, primer, masking tape and poly sheeting, a tack rag, polishing compound, touch-up paint and clear coat. Choose a calm, overcast day and block out the full day to fix the most common rust spots on the hood and doors.

You can buy automotive touch-up paint in pints and quarts to use in a spray gun, in aerosol cans, or in roller ball applicators. Even if you know how to use a spray gun, mixing automotive paint with a reducer to match the temperature and humidity conditions can be mighty tricky. We don’t recommend it. Instead, buy aerosol cans for larger repairs and roller ball applicators to fix scratches.

In order to buy the perfect colour match for your vehicle’s factory paint, you’ll first need to find the car manufacturer’s paint code. It can be in a variety of places on the body, in the engine compartment or trunk, or other places. Use either of these online resources to find instructions on how to locate your paint code: automotivetouchup.com or duplicolor.com.

Most late-model vehicles were painted with base coat/clear coat paint. The base coat contains just the pigment and binding resins—the clear coat is just the gloss. You’ll need equal amounts of both. You’ll also need an epoxy self-etching primer to bite into the bare metal and a lacquer primer to hold the paint. We used paint, primer and sanding supplies from automotivetouchup.com for this repair. The Dupli-Color brand is available at most retail auto parts stores, car dealers and online retailers. Or, you can buy automotive paint locally from a professional auto body supplier.

Next, buy 40-, 600- and 1,000-grit sandpaper, a sanding block, grease and wax remover, poly sheeting, painter’s tape, a tack rag and a microfibre cloth.

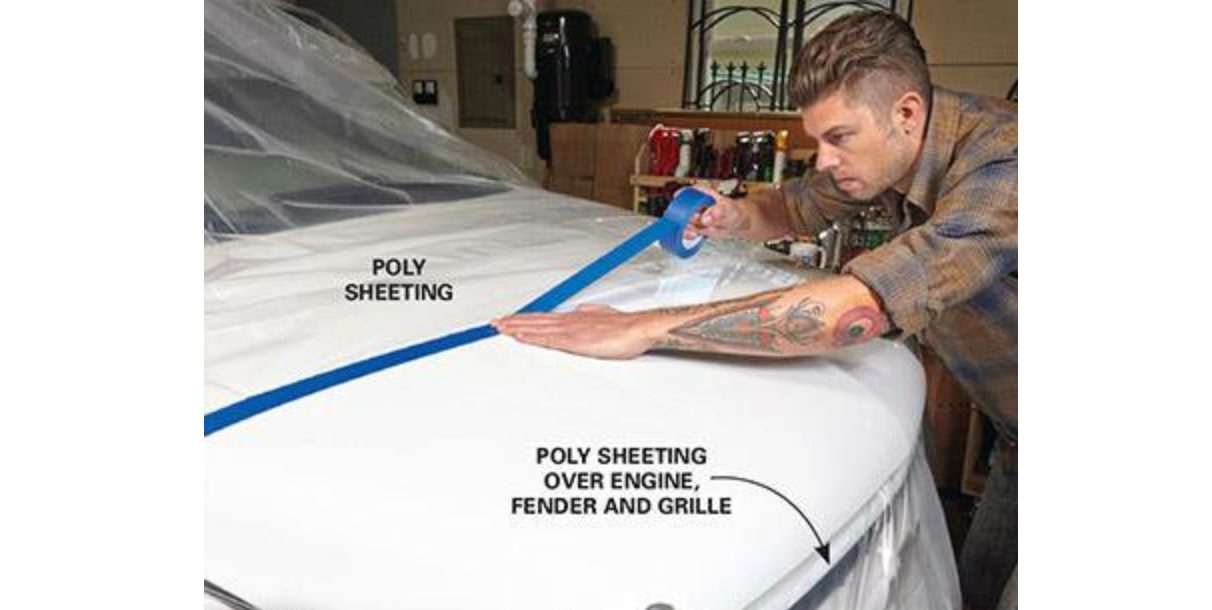

Step 1: Mask off the car rust repair area

Protect the entire vehicle from paint overspray with poly sheeting. If you’re painting the hood, spread poly sheeting over the engine and fenders. In door areas, cut poly sheeting to fit the door opening and tape it to the jamb. The final masking must be a foot or two away from the repair area so you’ll have room to blend the touch-up paint into the good areas.

Got a chip instead of full-blown rust? Check out this expert advice on how to fix paint chips.

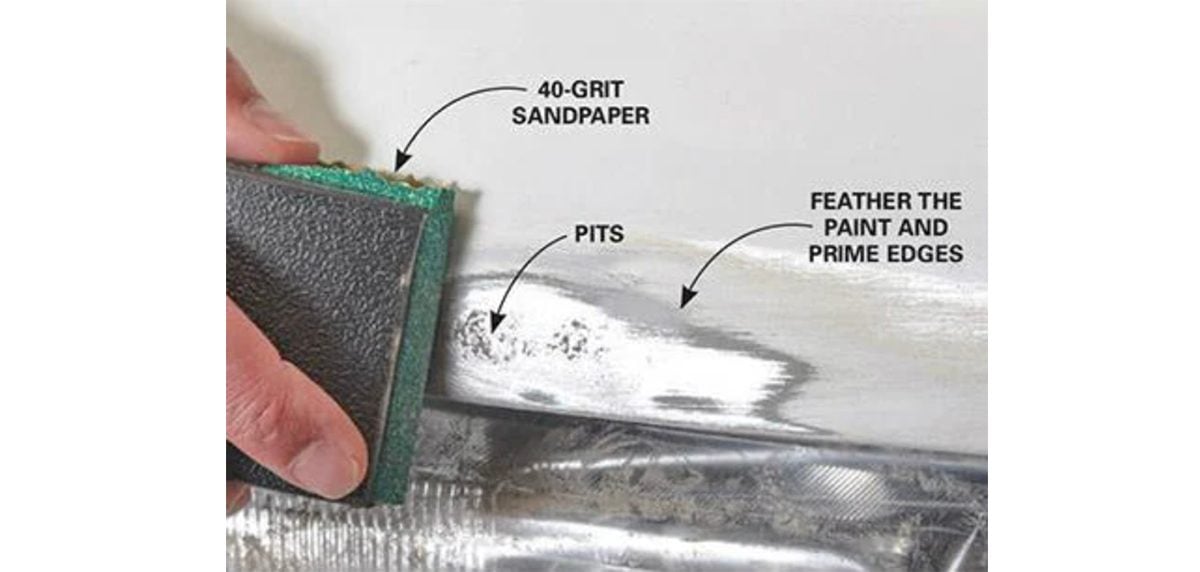

Step 2: Remove the rust

Crack off any blistered paint with a scraper. Then sand the rust using 40-grit sandpaper, sanding through the rust spots, down to bare metal. Then enlarge the sanded area so you’ll have space to feather the edges. Then feather the paint edges using 120-grit sandpaper. Complete the feathering with 220 grit. Use a tack rag to remove particles from the unmasked area. If the rust has created pits in the metal you can fill them now with body filler or wait until the epoxy primer dries and apply multiple coats of filler primer.

Check out more smart uses for sandpaper.

Step 3: Clean with detergent

Clean the entire unmasked area with a grease-cutting dishwashing detergent, followed by clean rinse water. Let it dry. Then wipe the area one more time with a lint-free cloth to remove any remaining dust or lint. Apply the paint manufacturer’s prep solvent.

Find out 13 car washing tips the pros don’t want you to know.

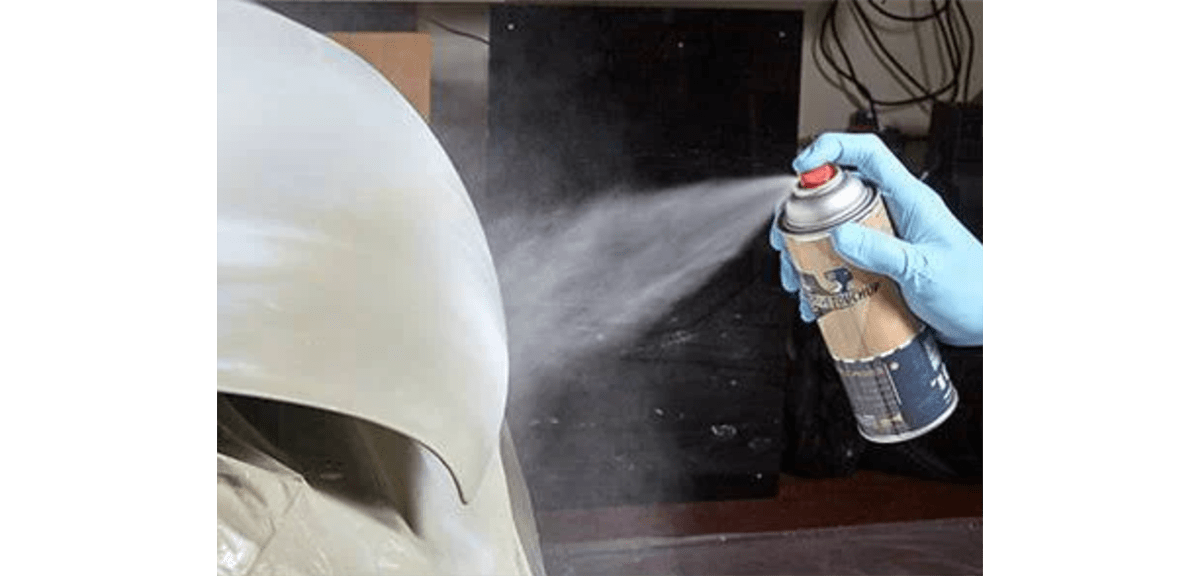

Step 4: Prime the surface

Apply epoxy primer, then filler primer. Spray the filler primer in heavier coats to cover the entire repair area. Move the can away from the surface slightly and blend it into the surrounding painted area. Self-etching epoxy primer provides a strong bond to bare metal, so use it as your first coat. Spray two to three medium coats, allowing the recommended wait time listed on the label (usually 15 minutes) between coats. Wait a full hour for the epoxy to dry to the touch (longer if it’s humid outside). Sand the epoxy primer with wet 1,000-grit sandpaper. Wash with clear water and let dry. Wipe the dried epoxy primer with a lint-free cloth and apply two to three heavier coats of lacquer filler primer allowing drying time between each coat. Let the lacquer primer dry until it’s dry to the touch—at least one hour—before sanding.

Step 5: Sand the primer

Sand drips and sags with 320-grit sandpaper. Then final-sand the entire repair area. Starting with wet 600-grit sandpaper, smooth the primer and feather the edges. Then switch to wet 1,000-grit sandpaper to final-sand the entire repair, including the blended areas.

Here are 20 essential tools for the home mechanic.

Step 6: Spray the base coat

Apply the coloured base coat. Start at the bottom of the repair and apply the colour coat in left-to-right rows, overlapping each pass by about one-third. Build the colour slowly into the repair and surrounding areas in two to three coats, allowing about 10 to 15 minutes between coats. Holding the spray can about 12 inches away from the surface, spray the repaired area. The slower you build the colour coat, the better it’ll look under the clear coat. Allow the base coat to dry, until it’s dry to the touch, at least 60 minutes. Don’t sand the base coat (especially metallic colours) unless you’ve created sags. In that case, sand lightly and then respray the touched-up areas.

Step 7: Spray on the clear coat

Apply several coats of clear coat, allowing the recommended drying time between coats. Gradually work the clear coat into the surrounding painted areas to achieve a smooth blend line. This is the hardest part because all clear coats run easily and that will ruin the look of your paint job. If you create a run in the clear coat, you’ll have to let it dry for at least 48 hours before attempting to fix it with fine-grit sandpaper and polishing compound. Then you’ll have to respray the sanded area. So practice spraying on a scrap piece of cardboard to get a feel for the nozzle and the speed of application.

Using an old cotton T-shirt or microfibre cloth and buffing compound, hand-buff the repaired area. Don’t use a polishing machine for this step. Wait at least 30 days before waxing.

Now that you know how to repair rust, find out which rust proofing option is right for you.