The Advantages of Using a Torque Wrench

You may think you don’t need a torque wrench to install spark plugs or work on your lawn and garden equipment. But studies show that most DIYers overtighten just about everything. And overtightening leads to broken bolts, stripped threads and damaged equipment.

With a torque wrench and the manufacturer’s torque value in hand, the problem is solved: A “clicker” torque wrench makes an audible click when you’ve reached the set torque, and with a “beam”-style wrench, you just watch the scale and stop at the right number.

Torque Wrench Use and Care Tips

Tighten fasteners in two steps—first to half torque and then to final torque.

Clean dirty or rusted threads before tightening, but don’t lubricate them unless instructed to by the equipment manufacturer.

Always dial the wrench back to zero (never below zero) when you’re done with it.

Never use your torque wrench as a breaker bar—that’ll damage the torque mechanism.

Carry it with kid gloves—a single fall can knock the accuracy off by as much as 30 per cent. If you do drop it, get it recalibrated before using it again.

What to Look for in a Torque Wrench

Torque wrenches come in four styles: clicker style, bending beam, dual beam and digital. Dual beam and digital wrenches are the most expensive, and they’re overkill for most of us. You simply don’t need to spend that kind of money to get accurate results. As long as you follow our usage tips, you can torque nuts and bolts with any of these wrenches.

Clicker-Style Torque Wrenches

You’ll have to spend close to $100 to get a pro-quality ½-inch drive clicker-style torque wrench. Sure, it’s a lot more than for a cheapo wrench. But at least you’ll be getting a wrench that’ll hold its calibration longer. Better yet, most of these wrenches carry at least a one-year warranty and can be recalibrated and repaired after the warranty period.

Bending Beam Torque Wrenches

A bending beam (aka “deflecting beam”) torque wrench holds its calibration forever if you don’t drop it. I’ve owned one for 30 years, and it still works fine. You can buy them at home centres and online. The downside to a bending beam wrench: You must view the scale from directly above the needle. That’s hard to do when you’re using it in close quarters or at an angle.

Economy Clicker-Style Torque Wrenches

You can find economy clicker-style torque wrenches at most home centres and online. They work well if you just need a torque wrench for a single tightening project. But economy torque wrenches don’t hold their calibration very long, and most calibration services won’t recalibrate them. Consider it a disposable “one-project” tool.

Find out how long you can drive on a spare tire.

Set the Torque

Did you know there’s a right and a wrong way to tighten lug nuts? Most people think “tighter is better.” Not true. Overtightening lug nuts is the No. 1 cause of brake rotor lateral runout (warp). Warped rotors cause pedal pulsation and can increase your stopping distance. Overtightening is also a great way to break wheel studs. The stud itself doesn’t cost much, but the labour to press out the old stud and insert the new one can be significant.

Consult your owner’s manual or a shop manual and set your torque wrench to one-half the recommended torque specification.

Spin the lug nuts on by hand. Never coat the stud with grease, oil or anti-seize. Lower the jack only enough to bring the tire into contact with the road. Tighten each nut to one-half of the specified torque. Then lower the vehicle completely and tighten each nut to full torque.

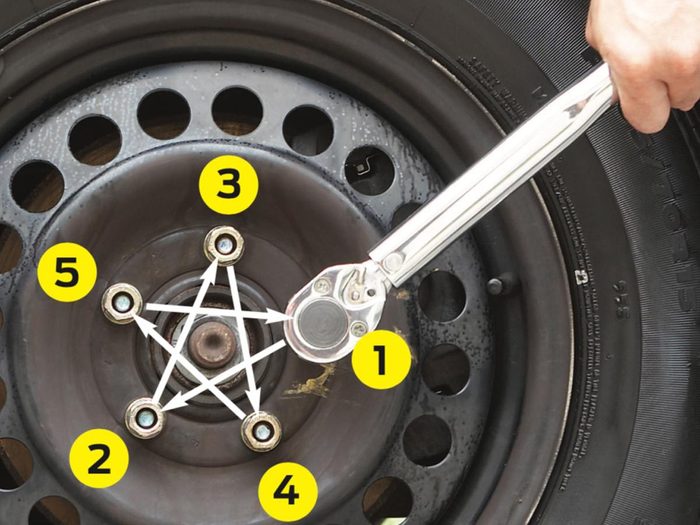

Lock in the Proper Torque, Then Tighten in sequence

Reset the wrench and tighten each nut to full torque. Move the socket from one nut to the next in a star-shaped pattern, tightening each as you go.

Now that you know how to use a torque wrench, check out 20 essential auto tools for the home mechanic.